Prototype faster delivery

OEM&ODM

20 Years High Precision Custom CNC Machining Service

Sheet Metal Fabrication with Server Chassis Enclosure

5 Years Alibaba Custom Manufacturer

ISO 9001 Certified & RoHS Certified

Cooperative Clients

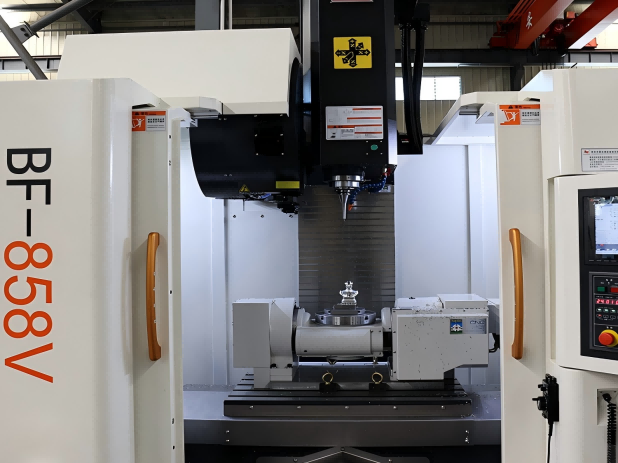

Set of CNC Machines

CNC Processing Factory

1. Mechanical Polishing & Sandblasting

Mechanical polishing: A mirror effect is obtained through physical grinding, suitable for metals such as stainless steel and aluminum.

Sandblasting (such as glass beads or aluminum oxide): Quickly remove knife marks, form a matte texture, and enhance coating adhesion.

2. Anodizing (mainly aluminum)

Hard anodizing: Improve the surface hardness of aluminum parts (up to HV1500), wear and corrosion resistance.

Ordinary anodizing: Can be dyed (such as gold, blue), with strong decorative effect.

3. Electroplating Process

Nickel plating/chrome plating: Enhance the rust resistance of metals (such as steel and copper), and chrome plating has strong reflectivity.

Galvanizing: Low cost, suitable for iron parts rust prevention.

4. Chemical Conversion Film

Passivation treatment (stainless steel/aluminum): Form an oxide film to prevent rust, and almost no change in size.

Phosphating treatment (steel): Improve paint adhesion, suitable for automotive parts.

5. Spraying & Powder Coating

Painting: Can be customized in multiple colors.

Powder coating: Cured by electrostatic adsorption, wear-resistant and UV-resistant.

Sheet Metal Fabrication Factory

1. Advantages of Stainless Steel

304 stainless steel: Advantages: strong corrosion resistance (food grade standard), good weldability, beautiful appearance.

430 stainless steel: Advantages: low price, good salt spray resistance (suitable for outdoor use).

2. Advantages of Aluminum and Aluminum Alloys

5052 aluminum alloy: lightweight (density 2.7g/cm³), salt spray corrosion resistance, easy anodizing and coloring.

6061 aluminum alloy: high strength, suitable for structural parts, excellent cutting performance, ordinary oxidation.

6063 aluminum alloy: medium strength (suitable for light loads), good ductility (easy to bend), and more beautiful anodizing effect.

3. Advantages of Copper and Copper alloys

Red copper (T2): excellent electrical/thermal conductivity, easy to stretch and form (such as heat sinks).

Brass (H62): good cutting performance, strong wear resistance (such as lock parts).

4. Advantages of Titanium

high strength and lightweight, strong corrosion resistance, and high temperature resistance.

Display of Different Product Materials

Stainless Steel

Aluminum Alloy

Copper Alloy

Titanium Alloy

Magnesium Alloy

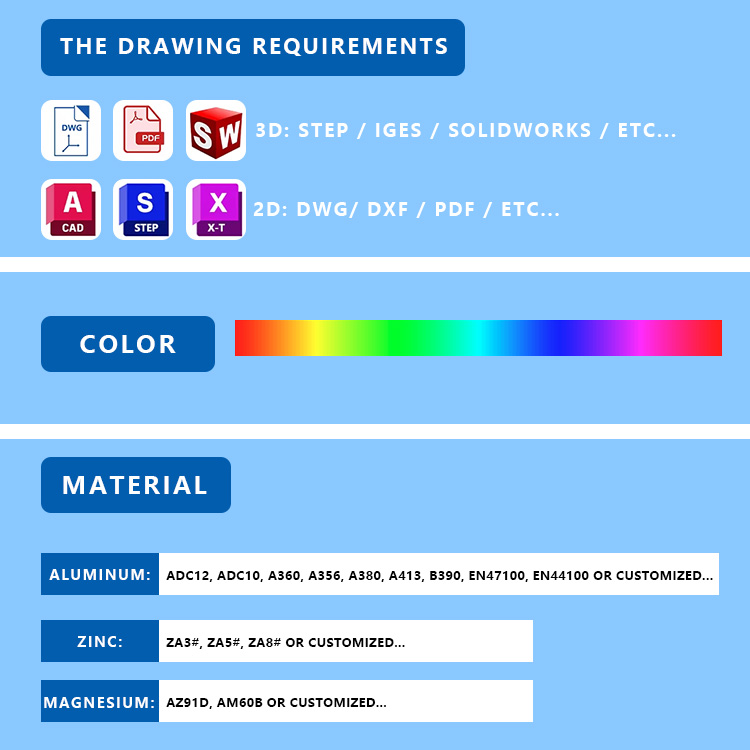

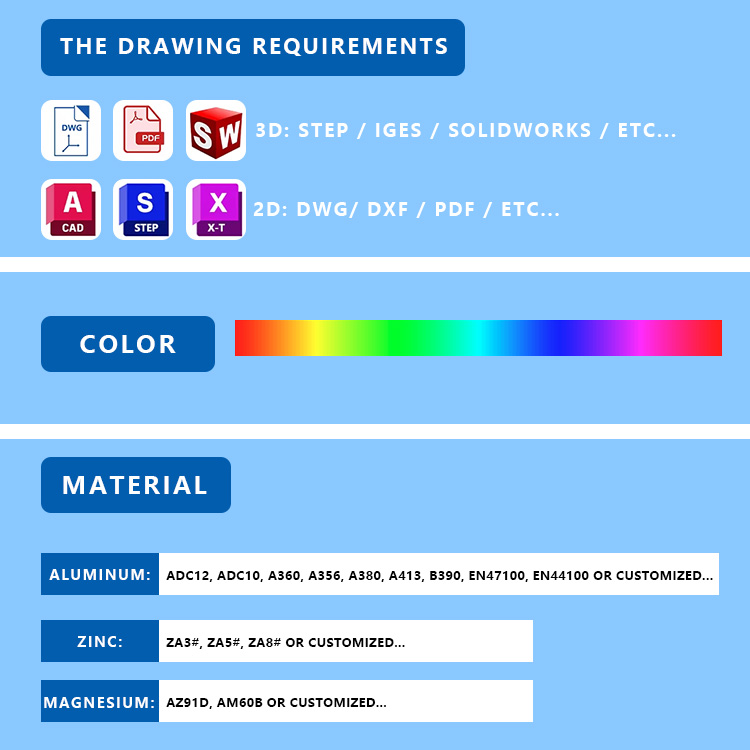

Our Services and Advantages

Our Services

- CNC machining department offer the OEM high precision metal or plastic machining services

- The CNC turning department off the OEM perfect finish plastic and metal turning parts

- The metal sheet fabrication department off you the high quality laser cutting , stamping, bending and welding services .

- We offer you the one step services ,the design problems solution , material advise ,surface treatment choice and support of after selling etc .

CNC Machining Advantages

- 20 Years High Precision CNC Machining Experience

- We have the senior engineer team and strict quality inspection system. It makes sure your project perfect .

- We use advanced CNC machine tools and high-precision measuring equipment to ensure that the dimensional error of processed parts is strictly controlled within ±0.01mm

- We have the senior engineer team and strict quality inspection system. It makes sure your project perfect .

Sheet Metal Fabrication Advantages

- Our sheet metal processing workshop's core services include high-precision laser cutting, stamping, bending and welding processes, which are suitable for the production of various complex shapes and high-standard sheet metal parts.

- The processing tolerance range can be accurately up to ±0.01mm to ±0.05mm, ensuring that each product can meet strict design requirements and quality standards.

- All processed parts are strictly surface treated after completion to ensure a smooth and delicate surface without scratches or defects, showing a high-quality appearance.